Reuters

The driver of a Tesla Model S crashed into a fire truck while driving down a California highway.

Tesla Inc is on track to achieve its production targets for the Model 3, the electric car-maker said on Thursday, squashing a report of further delays and quality issues for its latest and most-affordable sedan.

Quoting unnamed Tesla insiders, CNBC reported that there have been numerous problems with that machinery requiring the battery-carmaker to continue doing much of the battery pack production work by hand, but also forcing Tesla to bring in additional workers from both its battery partner Panasonic and from temp agencies.

More than 450,000 people have preordered the Tesla Model 3, the company's first mass-market sedan. This is where the problems arose. and according to the CNBC report, the employees said, "the complex and precise work is hard to accomplish manually, resulting in high scrappage rates and the risk that some battery packs could fail in the field". They went on, saying, "As with Model S and Model X, which have well demonstrated safety records, we maintain a rigorous approach to quality and process control for the Model 3 battery. This is something Elon and JB discussed extensively on our Q3 earnings call, and it has no impact on the quality or safety of the batteries we're producing".

That has raised the growing specter that Tesla will have to return to the equity markets to raise more capital, an irony considering the continuing strength of its stock.

But more recently, Kolodny acknowledges, Tesla has begun to ramp up production. The company will never deliver more than a token few for less than the current $49,000 lowest-cost offering. "And even at those higher prices Tesla will never come anywhere close to its promised [profitability]". Elon Musk has been in talks with Jeffrey Brian Straubel regarding the cuts in earnings by Tesla.

Tesla has a history of setting and missing ambitious targets. Nobody dressed up like Elon Musk or pitched a tent outside the showroom overnight to get an enviable place in line. In a shareholders' update in August, the company should be producing 5,000 Model 3s per week by the end of 2017. But while Musk also claimed production would ramp up rapidly, by the end of 2017, Model 3s were still being built at a much lower rate than previously promised. No $35,000 basic models have shipped as of mid-January.

With talking stick in hand, moderate senators broke the shutdown

The group that she pulled together has been around for some time, calling themselves the Common Sense Coalition. Dreamers have been able to work in the US without being deported under the DACA program.

CHAN 2018: Morocco beat Namibia 2-0 to clinch semi-final place

Namibia may well ask questions as to whether the ball was still moving and whether the free-kick was taken from the correct place. Morocco steadily took control and Loydt Kazapua was forced to palm away an effort which swirled towards him after 15 minutes.

How Analysts Rated The Priceline Group Inc

Colony Ltd Liability Corporation holds 278 shares or 0.03% of its portfolio. (NASDAQ:PCLN) for 289 shares. (NYSEAMERICAN:GSAT). The business services provider reported $35.22 EPS for the quarter, beating the Zacks' consensus estimate of $34.31 by $0.91.

The Tesla logo is shown during a display of alternative energy vehicles on Capitol Hill June 12, 2008 in Washington, DC.

"To be absolutely clear, we are on track with the previous projections for achieving increased Model 3 production rates that we provided earlier this month", the corporate statement read. "There are questions of tolerance and risk, what meets quality criteria and so on", one said. Each battery pack contains four modules. Production is supposed to be entirely automated, so the company had to "borrow" dozens of workers from lithium-ion cell supplier Panasonic to complete work on the batteries. Those cells have to be precisely aligned. Workers are also still manually assembling batteries at the Gigafactory.

But bandoliers are tough to put together by hand.

A current Gigafactory engineer recalled that in December, factory workers were manually "slapping bandoliers together as fast as they possibly could", generating a lot of scrap in the process.

Tesla's gigafactory in Sparks, Nevada is just a three hour drive from Clayton Valley.

"In light of these facts, it's preposterous to suggest that a company as committed to safety as Tesla would allow untested or unsafe batteries to go in our vehicles".

Recommended News

-

US, Poland oppose gas pipeline linking Russian Federation to Germany

Tillerson encouraged further such sales and spoke in favour of a pipeline that would run from Poland to Norway. Poland began importing liquid natural gas from the US past year .What Analysts Think of Denbury Resources (DNR)?

The stock of United Technologies Corporation (NYSE:UTX) has "Buy" rating given on Monday, January 8 by Goldman Sachs. Vanguard Group stated it has 0% of its portfolio in Intercept Pharmaceuticals, Inc. (NYSE: DNR ) for 156,140 shares.West Ham United's Arthur Masuaku sent off for spitting

Cook's side are top of League One for a reason and they combined sweat with skill superbly at the DW Stadium. Liverpool play West Brom at Anfield late on Saturday. -

Cilic in firing line as Federer eyes another title

It features the world's two highest-ranked players and will end with one of them winning their first grand slam. I did see today why he beat the players like Novak, Sascha [Zverev], other players in the past.Spain's top court rejects arrest warrant for Catalonia leader Puigdemont

Torrent said he has written asking Prime Minister Mariano Rajoy to meet and talk about the "abnormal situation" in Catalonia. The Catalan parliament must hold its first round of voting a new regional leader no later than January 31.Wild bison herd adopts escaped cow in Poland

But the presence of the herd could have kept her safe from wolves throughout the winter. The reddish brown cow visually stands out among the larger dark brown animals. -

Kylie Jenner Reportedly Enjoys 'Low Profile' Life With Boyfriend Travis Scott

And as her due date grows closer, 's family is still anxious that the 20-year-old is too young to be a mother, a source told. But a source told Entertainment Tonight: "Kylie has been chilling at home for the most part and just living her best life".Federer Reaches 30th Slam Final

He also almost did it in the 2016 Wimbledon quarterfinals before Federer saved three match points and prevailed in five sets. Chung also believed the experience will prepare him better for the rigors of best-of-five-set tennis at Grand Slams.Melania Trump Aide Fed Up With 'Salacious…False Reporting'

It didn't help that Monday, the 13th anniversary of the Trumps' wedding, passed without any public acknowledgment by either. The new decision was made based on "scheduling and logistical issues", according to the White House official. -

Gusty Winds And High Temps Raise Red Flag Fire Warnings

The advisory also states there will be "low relative humidity" and dry vegetation, leading to "critical fire danger". Red-flag warnings put fire agencies on alert that conditions for potentially rapid fire growth are in play.Pounding Higher, Is There More to Come From: Raytheon Company (NYSE:RTN)

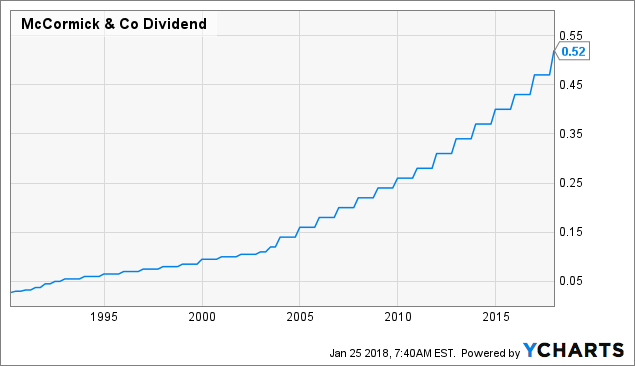

Uss Investment Management Ltd decreased Wells Fargo Co New (NYSE:WFC) stake by 1.24M shares to 5.12M valued at $282.25M in 2017Q3. Following the completion of the sale, the vice president now owns 28,311 shares in the company, valued at $5,354,459.43.McCormick & Company, Incorporated (MKC) Stock Price Up 0% Following Strong Earnings

Director, Hrabowski Freeman A Iii, sold 3,000 common shares of McCormick & Company, Incorporated (MKC) in the open market. Davis R M Inc increased Ishares Russell 1000 Growth Et (IWF) stake by 2,598 shares to 6,972 valued at $872,000 in 2017Q3.